Create a multi-level list computer software gdz. Electronic applications. How to split a page into columns of different widths

TO category:

Machines and installations for processing non-metallic materials

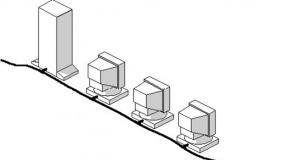

Cement guns (installations for pneumatic spraying of concrete mixture)

Cement guns are designed for shotcrete - applying layers of compacted concrete mixture to the concrete surfaces of tanks, tunnels and other concrete structures using compressed air for the purpose of waterproofing or decorative properties. The concrete mixture is ejected from the nozzle at a speed of 50...70 m/s and forms a dense layer on the concrete surface.

Rice. 1. Cement gun

Cement gun SB-13 (S-320) (Fig. 2) is intended for applying a compacted layer of cement-sand mixtures on the surfaces of various types of industrial, hydraulic and road structures. The cement gun is a continuous unit and consists of a hopper with a mesh, a sluice drum, a dispenser with a drive mechanism and an electric motor, a running gear, a water pump, a nozzle and connecting hoses.

Rice. 2. Cement gun SB-13 (S-320):

a - general view; b - design diagram; 1 - electric motor; 2 - water pump; 3 - outlet pipe; 4 - bunker; 5 - clamping ring; 6 - switch; 7 - clamping bolt; c - base of the bunker; 5 - dispenser cavity; 10 and 12 ‘sealing discs; 11 - sluice drum; 13 - incentive

The dry mixture is fed to the bunker mesh and sifted. Through the holes of the upper sealing disk, the mixture enters the cells of the sluice drum. The latter, continuously rotating, delivers the mixture to the discharge hole of the lower sealing disk, from where it spills into the dispenser cavity. The pockets of the rotating wing drum of the dispenser are filled with portions of the mixture and transfer it from the upper to the lower position. In this case, the pockets fall under a stream of compressed air supplied to the cement gun from the compressor, the mixture is blown in the longitudinal direction and carried into a rubber hose attached to the dispenser lid. At the end of the hose there is a spray nozzle, to which water is supplied from the water pump. In the nozzle, the dry mixture is mixed with water and then thrown at high speed onto the surface to be treated.

To waterproof rooms such as swimming pools, reservoirs, and damp basements, dense waterproof plaster - shotcrete plaster - is used.

Shotcrete plaster is applied using a cement gun. The method of applying plaster with a cement gun is called shotcrete. Shotcrete occurs under high pressure of compressed air, due to which the solution jet is imparted a high speed.

A layer of shotcrete plaster 15-25 mm thick applied to the surface is a fairly reliable waterproofing, since the applied solution is highly compacted. After 28 days of hardening under natural conditions, shotcrete plaster reaches a tensile strength of 15 kg/cm 3 .

Shotcrete plaster is applied using a unit that includes a cement gun, an air purifier, a water tank and a compressor. The main machine is a cement gun.

Cement guns come in various brands: SSSM-067, S-165A, S-165B, S-320A and 0-54. Regardless of the design of the cement gun, the operating principle is the same.

Cement gun SSSM-067 (Fig. 128, a) consists of the upper 11 and lower 15 truncated cones-reservoirs, or chambers, fastened into one whole.

Rice. 128. Section of cement guns:

a - cement gun SSSM-067, b - cement gun S-165B; 1 - motor, 2 - distribution plate, 3 - dry mix ripper, 4 - special tube, 5 - rubber gaskets, 6 - upper bell-shaped shutter, 7 - loading funnel, 8 - lever handle, 9 - upper lever handle, 10, 13 - taps for supplying compressed air to the upper and lower chambers, 11 - upper cone chamber, 12 - lower lever handle, 14 - lower valve, 15 - lower cone chamber, 16 - neck of the pipe, 17 - pipe, 18 - upper chamber, 19 - down Cam

The upper tank has a loading funnel through which it is filled with dry mixture. A steel pipeline runs from the outside of the housing; Flexible hoses are connected to it from the compressor. Compressed air is supplied to the cement gun through these hoses.

Cement gun S-165B (Fig. 128, b) has the same device as SSSM-067. It can also be used as a sandblaster to clean the surfaces of various structures from dirt, soot, and rust.

An air purifier is necessary to clean the compressed air pumped by the compressor into the cement gun.

The air cleaner is a welded cylinder. At the top of the bottom there is an inlet pipe to which a hose is connected to supply compressed air from the compressor. The lid has an outlet pipe: an air hose is connected to it, supplying compressed air purified from water and oil to the cement gun. Inside the air purifier there is a porous porcelain filter that cleans the air supplied by the compressor from dust, moisture and oil.

Before applying shotcrete plaster, water is supplied to the nozzle at a pressure 0.5 atm higher than the air pressure in the cement gun. This can be achieved by connecting a water hose to the water supply. If there is no water supply or there is very little pressure in it, then a special tank is used to supply water, to which a compressor is connected, with which you can increase the pressure.

Rubber hoses are used to connect the cement gun, air cleaner, water tank and compressor, as well as to supply water to the workplace from the cement gun to the dry mixture nozzle and from the water tank.

The hoses through which the dry cement-sand mixture is supplied are called material, through which air is supplied - air, and through which water - water. For strength, the hoses are reinforced with 3-5 layers of cord (special durable fabric). The hoses are covered with soft, wear-resistant rubber on the inside, and harder rubber on the outside, which protects them from being pressed through.

Material hoses are produced with a diameter of 25-38 mm. It is more advisable to use hoses with a diameter of 32 mm. The use of hoses of smaller diameter reduces the productivity of the cement gun and leads to the rapid formation of plugs.

Water hoses are used with a diameter of 13 mm. The individual hose sections are connected with screw-on couplings. Couplings with hoses are fastened with rivets or countersunk bolts. To prevent hoses from leaking air, the connections must be strong and tight.

A nozzle is used to mix the dry mixture with water and apply the solution to the surface (Fig. 129). The nozzle consists of a body 1 and a ring-shaped chamber with inserted mixers 2. The mixer is a ring with eight oblique radial holes. A metal conical barrel 3 with an internal rubber liner 4 is attached to the mixer body on the front side, protecting the barrel from rapid abrasion. WITH back side In the housing, a material hose 5 is secured with a half-nut, through which the dry mixture is supplied to the nozzle.

Rice. 129. Nozzle for applying solution:

1 - body, 2 - mixer, 3 - conical barrel, 4 - rubber liner, 5 - material hose, 6 - pipe, 7 - valve, 8 - water hose

At the top of the body is attached a pipe 6 with a valve 7, a water hose 8 is attached to the valve. The water supplied from the pipe enters the mixing chamber in streams and, meeting the cement-sand mixture, is mixed and a solution is formed. The solution is forcefully ejected by compressed air from the nozzle onto the surface, penetrates into all its irregularities and is firmly connected to it.

More advanced are the cement guns S-320A and 0-54. They have water pumps that can supply water at the right pressure to the nozzle from any source. They can operate without an air purifier, which makes the unit more compact.

In addition, they are mobile continuous machines.

Cement gun S-320A (Fig. 130) is intended for applying a waterproofing layer to various surfaces, for cleaning them with an air-sand jet. It consists of a hopper 4, a housing, four wheels, a sluice drum 5, a dispenser 10 with a drive mechanism and a water pump. Hopper 4 has a mesh, which is necessary for control sifting of the dry mixture.

Rice. 130. Section of cement gun S-320A:

1 - bracket ring, 2 - hopper base, 3 - incentive, 4 - hopper, b, 9 - rubber gaskets, 6 - handwheel, 7 - sluice drum casing, 8 - sluice drum, 10 - dispenser

An electric motor is installed on the cement gun; it drives the dispenser and the gear water pump, which supplies the nozzle with water.

Technical characteristics of the cement gun S-320A

The 0-54 cement gun is a smaller version of the S-320 cement gun. The productivity of the cement gun 0-54 is lower. Its main purpose is to clean facades using air-sand and water-emulsion mixtures, as well as to apply compacted plaster in one layer.

Technical characteristics of cement gun 0-54